What is NM500 Abrasion Resistant Steel?

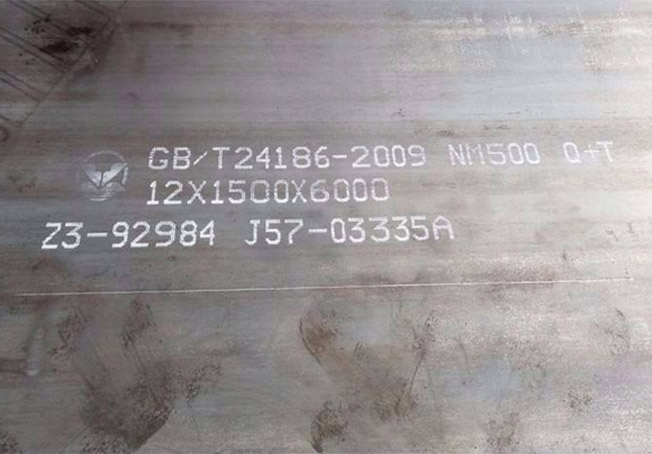

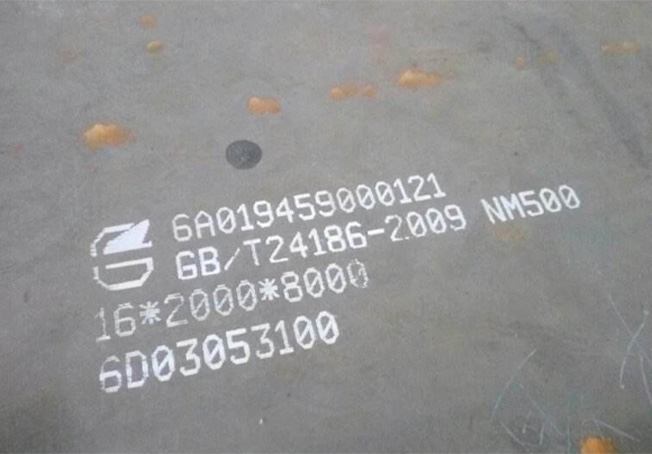

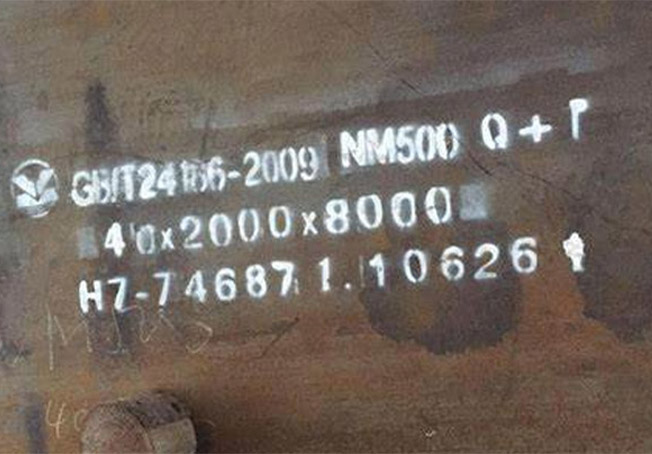

NM500 steel is a steel grade in the national standard GB 24186. NM 500 steel is a high-strength, wear/abrasion resistant steel known for its exceptional hardness and durability. This steel is specifically designed to withstand high wear conditions and provide longer service life in challenging environments. With a hardness range of 470-540 HBW, NM500 is widely used in applications where wear resistance is a top priority, such as mining equipment, construction machinery, and other heavy-duty applications. NM500 wear-resistant steel is more than 3 times stronger than ordinary low-alloy steel plates, and wear resistance can be improved by 2-3 times, significantly extending the service life of the steel plates.

NM500 Wear Resistant Steel Parameter:

NM500 AR plate steel chemical composition:

| Plate | C | Si | Mn | P | S | Cr | Ni | Mo | B | CEV | CET |

| thickness mm | max % | max % | max % | max % | max % | max % | max % | max % | max % | typv | typv |

| 4-13 | 0.27 | 0.7 | 1.6 | 0.025 | 0.01 | 1.00 | 0.25 | 0.25 | 0.004 | 0.49 | 0.34 |

| (13)-32 | 0.29 | 0.7 | 1.6 | 0.025 | 0.01 | 1.00 | 0.50 | 0.30 | 0.004 | 0.62 | 0.41 |

| (32)-40 | 0.29 | 0.7 | 1.6 | 0.025 | 0.01 | 1.00 | 1.00 | 0.60 | 0.004 | 0.64 | 0.43 |

| (40)-80 | 0.30 | 0.7 | 1.6 | 0.025 | 0.01 | 1.50 | 1.50 | 0.60 | 0.004 | 0.74 | 0.46 |

NM500 wear resistant steel plate mechanical property:

| Grade | Mechanical Property | Charpy V Impact Test | |||

| NM500 | HBW Thickness/Mpa | Elongation | Degree | longitudinal | |

| 4-32MM | 470-530 | Min % | -40 | J | |

| (32)-80 | 450-540 | 10 | 40 | ||

Features of NM450 Wear Steel Plate :

- High Hardness: NM500 wear plate steel has a hardness range of 470-530 Brinell Hardness (BHN) and has excellent resistance to penetration and deformation.

- Excellent Toughness: It has good toughness, allowing it to withstand repeated impacts and resist fracture.

- Excellent Wear Resistance: NM500 wear resistant plate is specifically designed to resist wear and abrasion from harsh materials such as rock, gravel and sand.

- Weldability and Machinability: NM500 wear steel plate has good weldability and machinability, making it easy to fabricate and customize.

- Thoroughly Hardened: NM500 wear resistant steel maintains its hardness throughout the plate thickness, ensuring consistent performance.

NM500 Abrasion Resistant Plate Dimensions Sizes:

| Thickness | Width | Length |

| 5 mm | 2000 mm | 6000 mm |

| 4 mm | ||

| 6 mm | ||

| 6 mm | ||

| 8 mm | ||

| 10 mm | ||

| 8 mm | ||

| 15 mm | ||

| 12 mm | ||

| 20 mm | ||

| 16 mm | ||

| 32 mm | ||

| 25 mm | ||

| 50 mm | ||

| 40 mm | ||

| 60 mm | 1800 mm | 3400 mm |

Where is NM500 Steel Wear Plate Material Applications?

- Armor Plates: AR500 abrasion plate is often used in the production of armored vehicles, military equipment, and protective structures.

- Target Systems: AR500 abrasion resistant steel sheets are used in shooting ranges and target systems because they can withstand repeated impacts from projectiles.

- Wear Plates: AR500 abrasion resistant metal is used in high-wear applications such as chutes, hoppers, and crushers in the mining and construction industries.

- Bulletproof Vests: Due to its excellent hardness and toughness, AR500 wear resistant metal is sometimes used in the manufacture of bulletproof vests for personal protection.