What is NM450 AR steel?

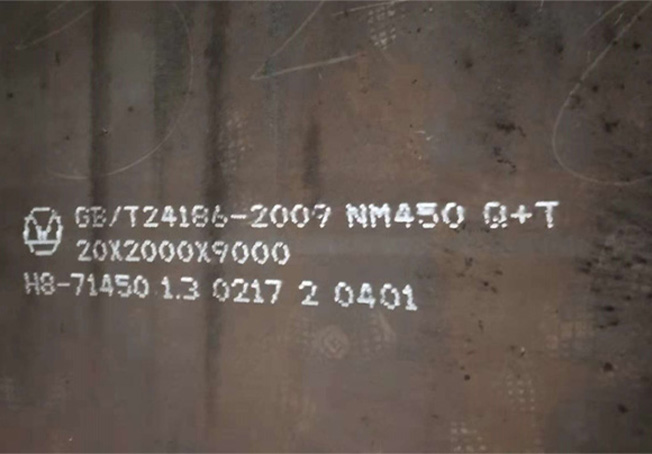

NM450 steel is a kind of domestic wear-resistant steel plate. After hot rolling, it is heat treated by direct quenching and tempering and reheating quenching and tempering processes. It has high mechanical strength, which is 3 to 5 times that of ordinary low-alloy steel plates. The surface hardness can be significantly improved, generally reaching 360~450HB.

NM450 Abrasion Resistant Steel Plate Parameter:

| NM450 Chemical Compositiom | |||||||||||

| Plate | C | Si | Mn | P | S | Cr | Ni | Mo | B | CEV | CET |

| thickness mm | max % | max % | max % | max % | max % | max % | max % | max % | max % | typv | typv |

| 3-(8) | 0.19 | 0.7 | 1.6 | 0.025 | 0.01 | 0.25 | 0.25 | 0.25 | 0.004 | 0.41 | 0.30 |

| 8-20 | 0.21 | 0.7 | 1.6 | 0.025 | 0.01 | 0.50 | 0.25 | 0.25 | 0.004 | 0.47 | 0.34 |

| (20)-40 | 0.23 | 0.7 | 1.6 | 0.025 | 0.01 | 1.00 | 0.25 | 0.25 | 0.004 | 0.57 | 0.37 |

| (40)-50 | 0.23 | 0.7 | 1.6 | 0.025 | 0.01 | 1.40 | 0.25 | 0.60 | 0.004 | 0.59 | 0.36 |

| (50)-80 | 0.26 | 0.7 | 1.6 | 0.025 | 0.01 | 1.40 | 1.00 | 0.60 | 0.004 | 0.72 | 0.41 |

| Mechanical properties of NM450 | |||||

| Thickness/mm | ReL /MPa | Rm /MPa | A/% | Hardness/ HBW10/3000 | Impact -20℃ /J |

| 8 | 1250 | 1460 | 16 | 445 | 40 |

| 12 | 1290 | 1470 | 17 | 462 | 43 |

| 20 | 1370 | 1450 | 17 | 473 | 42 |

| 25 | 1230 | 1480 | 16.5 | 465 | 43 |

Benefits of NM450 Wear Steel Plate :

NM450 steel wear plates ensure unmatched performance, cost savings and longer life for your equipment. Whether you are reducing weight or adding strength in applications such as truck bodies, dump truck bodies, containers and buckets, or need production wear parts that outlast other materials, NM450 is the best choice.

The outstanding performance characteristics of NM450 wear plates come from a combination of hardness, strength and toughness. As a result, nm450 can withstand sliding, impact and extrusion wear. nm450 goes beyond wear resistance, allowing you to protect your equipment investment and work more efficiently.

In truck bodies and containers, NM450 ensures longer service life and highly predictable performance. Its high strength and hardness often allow the use of thinner plates, resulting in higher payloads and better fuel economy.

NM450 in buckets means longer equipment life and increased reliability due to its excellent wear and deformation resistance. Enhanced performance is achieved because the wear resistance of NM450 is evenly distributed across the plate.

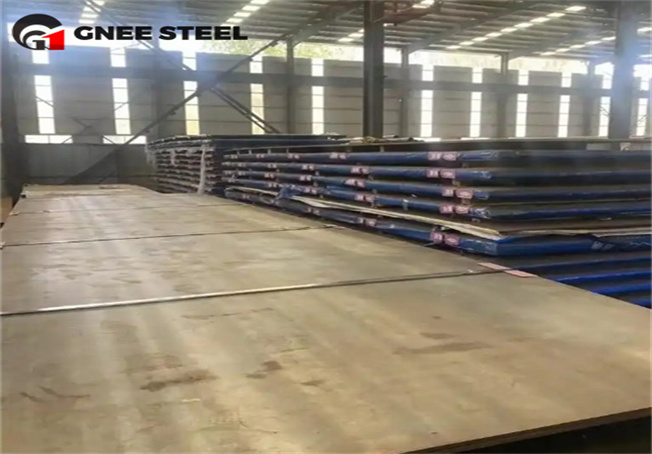

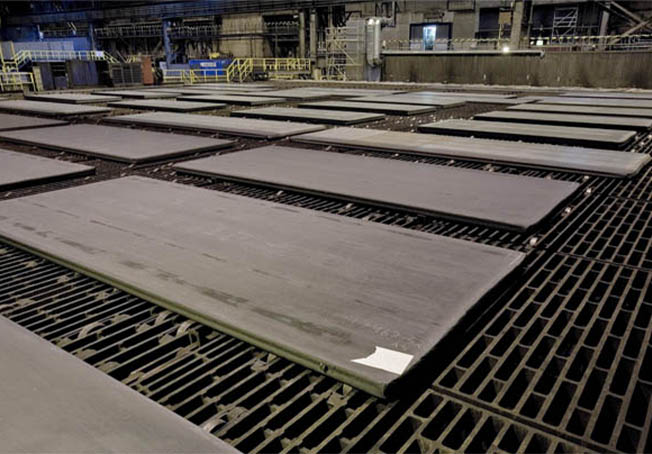

NM450 Abrasion Resistant Steel Plate Dimensions Sizes:

| Width | Thickness | Length |

| 2000 | 5 | 6000 |

| 2000 | 6 | 6000 |

| 1800 | 60 | 3400 |

| 2000 | 4 | 6000 |

| 2500 | 6 | 6000 |

| 2500 | 8 | 6000 |

| 2000 | 8 | 6000 |

| 2000 | 12 | 6000 |

| 2000 | 10 | 6000 |

| 2000 | 15 | 6000 |

| 2000 | 20 | 6000 |

| 2000 | 16 | 6000 |

| 2000 | 25 | 6000 |

| 2000 | 40 | 6000 |

| 2000 | 32 | 6000 |

| 2000 | 50 | 6000 |

Where is NM450 Wear Resistant Plate Used?

NM450 wear-resistant steel combines high strength, high hardness, high wear resistance, weldability, bendability and other characteristics, and is mainly used in:

1) Loader edge in loader industry

2) Wear-resistant lining in crusher industry.

3) Plate conveyor in coal mining machinery industry.

4) Coal mill lining in power industry.

5) Hopper lining in heavy-duty transport truck.