What is NM 600 abrasion resistant steel?

NM600 wear-resistant steel plate is a high-performance, high-strength wear-resistant steel plate. “N” stands for “resistant” in “wear-resistant”, “M” stands for “wear” in “wear-resistant”, and “600” means that its average Brinell hardness value reaches about 600. The implementation standard is GB/T 24186-2022 “High-strength wear-resistant steel plates and steel strips for engineering machinery”.

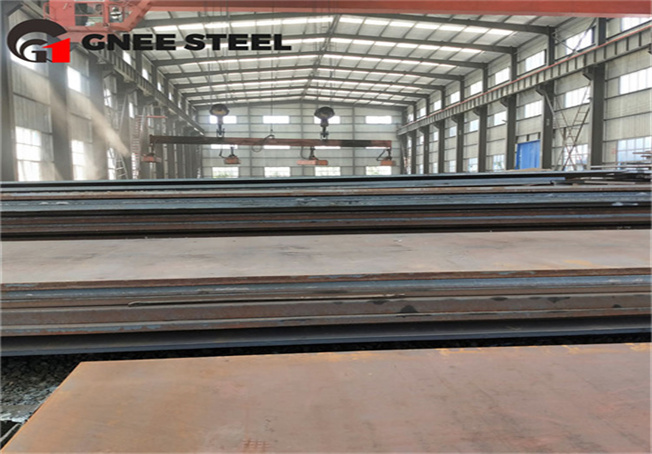

Performance characteristics of NM600 wear plate steel

High strength: tensile strength ≥ 600MPa, yield strength is also much higher than ordinary steel plates, and can withstand greater pressure and bending stress.

High wear resistance: After special manufacturing process and heat treatment, the wear resistance is 3-5 times that of ordinary steel plates, and it can maintain a long service life in a high wear environment.

High toughness: While ensuring high strength and wear resistance, it has good toughness and ductility, and can remain stable and reliable when subjected to impact and vibration.

Good processing performance: The steel plate has a smooth appearance and can be cut, bent, welded, etc. at room temperature or low temperature.

Corrosion resistance: It has good corrosion resistance and can maintain stability and reliability for a long time in harsh environments.

NM 600 Wear Resistant Plate Parameter

►Mechnical property for NM600 Abrasion resistance steel plate

| Tensile strength (≥Mpa) | -20℃ impacting test absorbed energy (Longi.J) | Elongation in ≥,% | HBW

Min |

| – | – | 50mm | 570 |

| – |

►Chemical composition for NM600 Abrasion resistance plate (Heat Analysis Max%)

| C | Si | Mn | P | S | Cr | |

| 0.45 | 0.70 | 1.90 | 0.020 | 0.010 | 1.50 | |

| Mo | Ti | B total | Als (min) | Ni | ||

| 0.80 | 0.050 | 0.0005-0.006 | 0.010 | 1.00 | ||

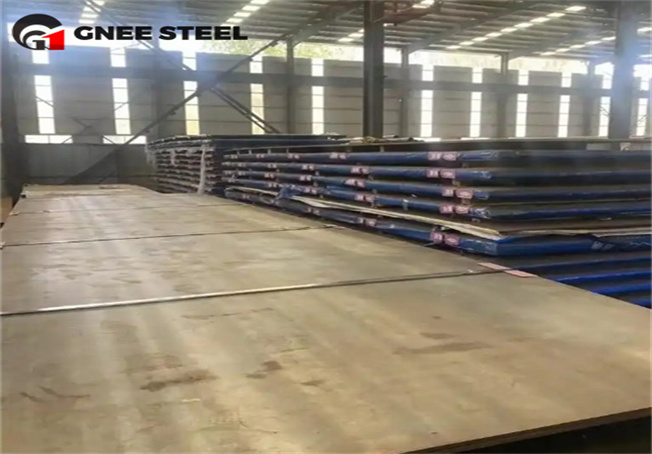

NM 600 Wear Resistant Plate Weight Sizes

Thickness

Standard range: 8~120mm (conventional production specifications), common order thickness is 10~70mm.

Special customization: can be expanded to 4~120mm (need to be adjusted according to the rolling process).

Width

Standard range: 1500~2500mm, typical specifications are 2000~2600mm.

Length

Standard range: 6000~12000mm, customized length can reach 13000mm (need to meet transportation conditions).

Implementation standards and tolerances

Standard basis: GB/T 24186-2022 (General specification for high-strength wear-resistant steel plates).

Thickness tolerance: Meet the requirements of ±0.5%~±1.0% in the standard (specific adjustment according to thickness grade).

Where is NM 600 wear steel plate used?

- For paper and pulp companies

- For high pressure applications

- For oil and gas industry

- For chemical refineries

- For pipelines

- For high temperature applications

- For water lines

- For nuclear power plants

- For food processing and dairy industry

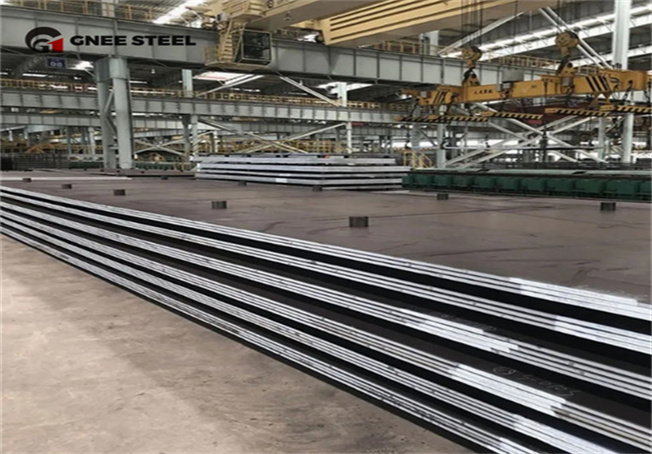

GNEE Steel is an abrasion steel manufacturer, wear steel plate supplier and resistant steel exporter. We are a company with 18 years of production experience, dedicated to providing abrasion plates of various materials.

The wear resistant steel we provide is strictly produced in accordance with the standards, has passed the quality certification, can provide quality certificates, and accept third-party testing.