BY  GENN

GENN

2024/06

Blog

Hardox 500 Steel: An Abrasion Resistant Steel with 500HB

This article describes the properties, applications, advantages, comparison with other steel plates, manufacturing and other recommendations of Hardox 500 wear plate. It describes the mechanical properties and chemical composition of Hardox 500 wear plate. This article also describes the difference between AR400 and AR500 wear plate. It describes that Hardox 500 is five times stronger and three times more wear resistant than mild steel.

What is Hardox 500 Steel?

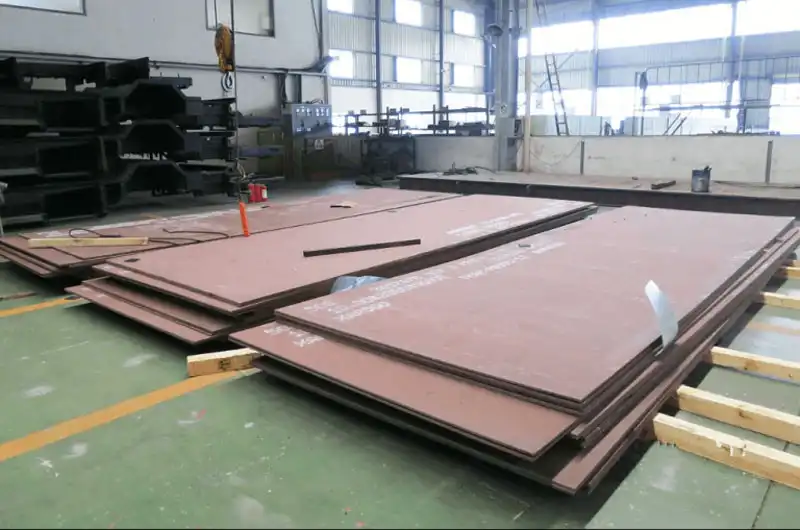

Hardox 500 is a bendable wear resistant grade. Hardox 500 wear resistant steel plates are engineered with premium chemical ingredients such as Carbon, Silicon, Nickel Molybdenum, Chromium, Boron, Sulphur, Manganese and Phosphorus. The premium ingredients embedded in Hardox® 500 wear plates give these modules enhanced corrosion resistance and tolerance. With a nominal hardness of 500 Brinell, these plates resist wear from stress-inducing systems. Hardox® 500 wear resistant plates offer good impact resistance and are not prone to sliding.

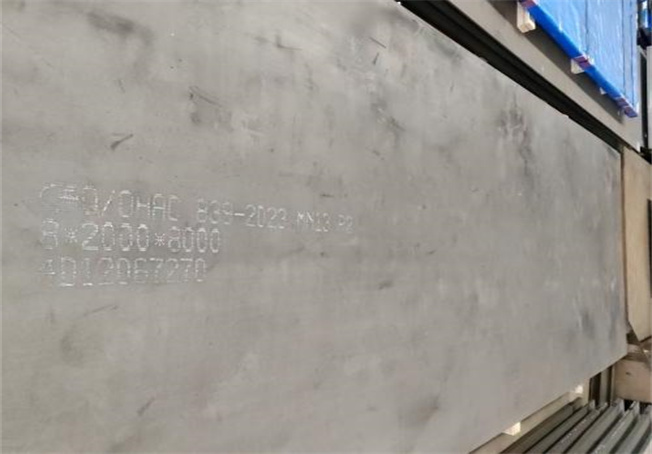

These robust plates are very effective in environments subject to abrasive media. Plates of this grade are typically designed with thicknesses starting at 6 mm and can extend to 100 mm or more as required. 500 HBW plates are designed with a density of 8 kg/m3, a typical yield strength of 1400 MPa and an impact energy of 37 J (-40 degrees Celsius).

What you need to know about the properties of Hardox 500 abrasion resistant steel plate plates

Hardox 500 wear resistant plate is known for its high wear and impact resistance. Made from quenched and tempered alloy steel, it offers excellent toughness and durability even under extreme conditions. Hardox 500 steel has a minimum hardness of 500 Brinell hardness and a typical hardness range of 500-550 Brinell hardness. It has excellent welding and bending properties, making it easy to use in a wide range of applications.

Hardox 500 wear steel plate is characterized by its ability to withstand harsh environments, high loads and intense wear. It provides maximum protection against abrasive and corrosive wear, making it ideal for heavy machinery and equipment applications. Hardox 500 wear resistant steel is also corrosion resistant, making it ideal for outdoor use. Its high strength-to-weight ratio makes it an excellent choice for weight-sensitive applications.

| Chemical Compositiom | |||||||||||

| Plate | P | Si | C | Mn | Ni | S | Cr | B | Mo | CET | CEV |

| thickness mm | max % | max % | max % | max % | max % | max % | max % | max % | max % | typv | typv |

| (40)-80 | 0.025 | 0.7 | 0.30 | 1.6 | 1.50 | 0.01 | 1.50 | 0.004 | 0.60 | 0.46 | 0.74 |

| (13)-32 | 0.025 | 0.7 | 0.29 | 1.6 | 0.50 | 0.01 | 1.00 | 0.004 | 0.30 | 0.41 | 0.62 |

| 4-13 | 0.025 | 0.7 | 0.27 | 1.6 | 0.25 | 0.01 | 1.00 | 0.004 | 0.25 | 0.34 | 0.49 |

| (32)-40 | 0.025 | 0.7 | 0.29 | 1.6 | 1.00 | 0.01 | 1.00 | 0.004 | 0.60 | 0.43 | 0.64 |

| Mechanical properties | ||||

| Mechanical Property | Charpy V Impact Test | |||

| HBW Thickness/Mpa | Elongation | Degree | longitudinal | |

| 4-32MM | 470-530 | Min % | -40 | J |

| (32)-80 | 450-540 | 10 | 40 | |

What are the uses of Hardox 500 wear resistant steel plates?

Hardox 500 wear steel plates have a wide range of applications in several industries. In the construction industry, it is used to make dump trucks, bulldozers, excavators, and other heavy machinery. In the mining industry, it is also used in blast furnaces, crushers, and conveyor belts. In the recycling industry, it is commonly used in shredders, balers, and waste separation equipment. Hardox 500 plates are used in the agricultural industry for plows, cultivators, and harvesters. The applications of Hardox 500 plates are endless and they have a wide range of uses in various industries.

Benefits of AR500 Wear Resistant Steel

The hardness and toughness of AR500 abrasion resistant plates make them extremely wear and impact resistant. These properties make AR500 steel a durable, long-lasting material, which is critical for applications that require a material that can withstand extreme wear and tear.

AR500’s wear resistance steel plate durability also means that the material needs to be replaced less frequently than less wear-resistant materials, which can reduce material costs and prevent devastating equipment failures.

Comparison with other steel plates

Hardox 500 abrasion resistant wear plates stands out from other steel plates due to its excellent properties. Compared to mild steel, Hardox 500 is five times stronger and three times more wear-resistant. Compared to AR400 steel plate, Hardox 500 has better impact resistance and can withstand higher loads. It also has better weldability and machinability than other high-strength steel plates.

Fabrication and other recommendations

Welding, bending and machining

1) It is recommended to contact us for technical support.

2) Bendability of plates complies with Hardox® Bend Assurance Class G. For thin plates, bendability complies with Hardox® Bend Assurance Class D.

3) Hardox® wear plate is not suitable for further heat treatment. It acquires its mechanical properties by quenching and, if necessary, by subsequent tempering. The properties in the delivery condition will not be maintained after exposure to temperatures exceeding 482ºF.

4) Appropriate health and safety precautions must be taken when welding, cutting, grinding or otherwise handling this product. Grinding, especially of primer-coated plates, may generate dust with a high particle concentration.